1200 SERIES PISTON

DIFFERENTIAL PRESSURE

Gauges ∙ Switches ∙ Transmitters

Heavy duty weatherproof design

● Measure up to 150 psi differential

● Handle up to 10,000 psi line pressure

● Popular in filtration, level and flow applications

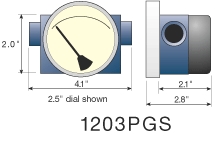

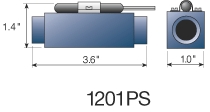

| Model | Differential pressure range | Maximum line pressure*/temp. | Accuracy (F.S.) | Electrical Available | Additional Information |

| 1201PG/PGS/PS PG (Piston Gauge) PGS (Piston Gauge-Switch) PS (Piston Switch) | 0-5 to 0-150 psid (0-0.33 to 0-10 bar) | 3000 psig (200 bar)/ 200F (93C) | 2% | 1 switch - no enclosure |

|

| 1202PG PG (Piston Gauge) | 0-5 to 0-150 psid (0-0.33 to 0-10 bar) | 5000 psig (340 bar)/ 200F (93C) | 2% | Not available |

|

| 1203PS/PGS PS (Piston Switch) PGS (Piston Gauge-Switch) PT (Piston Transmitter) PGT (Piston Gauge-Trans) | 0-5 to 0-150 psid (0-0.33 to 0-10 bar)

| 5000 psig (340 bar)/ 200F (93C) | 2% | 1 or 2 switches 1 relay transmitter Class 1 Div. 2 For Class 1 Div. 1 |

*Ask about our 10,000 psig line pressure units

|  |  |

Piston Sensor Differential Pressure Gauges

These piston sensor differential pressure gauges measure the pressure difference between two points. Acting in the place of two pressure gauges, these units allow for one simple reading on an easy-to-read scale.

Popular in filtration, flow and level applications, they are a low cost alternative to bourdon tube and bellows designs.

We offer them with bodies (and wetted parts) of aluminum, stainless steel, brass or PVC. A variety of dial sizes are also available, from 2.5 inch to 6 inch, with many porting and mounting configurations. Choose from a wide selection of standard options; enough to satisfy any requirement.

Note: Our piston sensor models are best for liquid applications as they have a slight amount of fluid migration from the high to low pressure ports. Select our diaphragm models for air or gas applications or where fluid migration cannot be tolerated.

Switches, Relays, Transmitters

A variety of reed switches, relays and transmitters can accompany the gauges or be supplied on their own, without a dial. SPST switches are offered normally open (N.O.) or normally closed (N.C.). SPDT switches also are available. DPDT relays are offered for high inductance applications, such as those incorporating motors or solenoids. Transmitters offer a wide variety of outputs, such as voltage, current, frequency or RS 232. Click here for more information on switches, relays and transmitters.

PISTON AND DIAPHRAGM

DIFFERENTIAL PRESSURE INSTRUMENTS

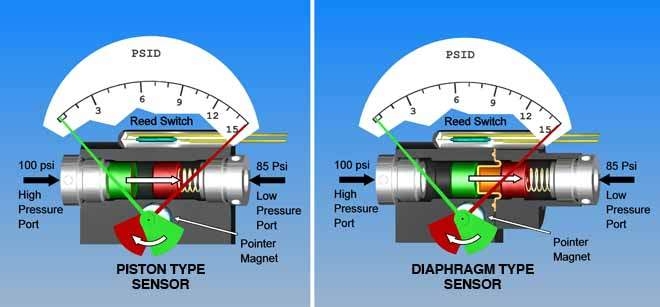

Below, a 15 psi differential in pressure results in movement of the spring-loaded sensor (piston or diaphragm) from the high pressure port to the lower pressure port (left to right). The sensor magnet induces a rotation in the pointer magnet and the attached pointer. The pointer reflects the 15 psi differential on the dial scale. A reed switch actuates as the sensor magnet moves into close proximity.

DIFFERENTIAL PRESSURE AND FLOW

| Gauge and Lens Options Plastic lens Shatterproof lens (n/a on 2.5") Liquid filling, glycerine Liquid filling, silicone Follower pointer Epoxy-coated dial case (n/a on 2.5") Lexan B style dial case (3.5" only)

Special Dial Options Red arc Multi-color arc Dual scale Square root flow, single scale Square root flow, dual scale Non-catalog ranges Clean/dirty dial High-density dial (4.5" min.) Service legend (one line) Dial artwork, B&W (1 time charge) Dial artwork, 2-color (1 time charge)*

*Need Pantone reference and sample or file | Alternate Port Sizes* 1/8" NPT 1/2" NPT MS or AND BSP

*Many types avail., contact factory

Elastomers* Buna-N o-ring seals Viton o-ring seals EPDM o-ring seals Fluorosilicone o-ring seals Teflon o-ring seals Buna-N diaphragm and o-ring seals Viton diaphragm and o-ring seals EPDM diaphragm and o-ring seals Fluorosilicone diaphragm and o-ring seals

*O-rings without diaphragms are for piston units

Alternate Body Materials* 1201 PVC body 1203 PVC body

Note: PVC has 100 psi max. line pressure rating *Others available upon request | Miscellaneous Options Teflon-coated magnet/spring Calibrate on steel Oxygen service High temperature service Stainless steel tag (with SS wire) Paper tag Reverse pressure Teflon-coated spring* (flowmeters) Teflon metering cone (flowmeters) Reverse flow (flowmeters) Vertical flow (flowmeters) Special calibration (flowmeters)

*Magnet is always Teflon coated on flowmeters

Transmitter Options Gauge-transmitter combo (PGT,DGT or FGT) Transmitter only, no gauge (PT, DT or FT)

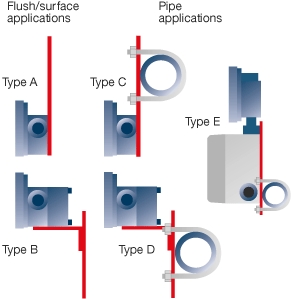

Rear and Pipe Mounting Brackets Type A, rear surface (1201, 1202, 1502, 1516) Type B, rear surface (1203, 1533, 1800) Type C, pipe (1201, 1202, 1502, 1516) Type D, pipe (1203, 1533, 1800) Type E, pipe (1204, 1304, 1504, 1514, 1904)

Certification Options Certification of Conformance Certification of Accuracy NACE Conformance (MR0175) Material Certification Certified Drawing

|

GAUGE CASE STYLES

Two Gauge Dial Case Styles

1 -- B "Basic": This case is the most popular choice since the gauge is often supported by the process line. An optional c-clamp is offered for panel mounting.

2 -- F "Flanged": This case has holes for panel mounting. Two or three holes are drilled in the flange to accept screws for flush mounting to the panel.

Dial Case Materials (these materials represent dial case only, not pressure body)

2.5" Dials: stainless steel

3.5", 4.5" & 6" Dials: cast and machined aluminum with a durable, black painted finish

Weather resistant: All of our cases are weather resistant. This feature also facilitates liquid filling, which is an option available on all standard gauges.

Mounting brackets: Click here to see other mounting options

Miniature Differential Pressure Indicators

Our miniature differential pressure indicators come standard with a weatherproof 1" molded lens. A special 2" dial also is available.

| ELECTRICAL DETAILS: DIFFERENTIAL PRESSURE AND FLOW INSTRUMENTS

Gauges ∙ Switches ∙ Transmitters

Switches and Relays :

Orange Research differential pressure and flow instruments are available with switches and relays to allow the user to be alerted of process conditions or control process equipment at pre-set values. We offer SPST, normally open or normally closed, and SPDT switches.

Our switches are hermetically sealed reed switches and come with or without enclosures, depending on the model. The models with enclosures have all of the common safety ratings to satisfy a variety of environments and markets. Select from Nema-4X to Class 1, Division 1 or 2, or UL, CSA, CE, or ATEX ratings just to name a few. For complete safety ratings or certifications refer to our individual model Specifications Sheets.

Most of our reed switches are field adjustable within the upper 70 or 80% of the full-scale range of the instrument, depending on the model. Refer to our Specification Sheets for details on each model. All switches are preset to full-scale range unless another value is specified at the time of order placement. When two switches are used they can be set independent of each other.

Our relays are best for high inductive circuits such as those incorporating solenoids or motors. We use a reed switch to actuate the relay at a prescribed value. This isolates the reed switch, protecting if from high current or voltages. Some models allow for two relays on one instrument.

Relays Available for Explosion-Proof Switches

*Instruments that accept two reed switches can be supplied with one SPST and one SPDT switch if desired. Refer to our individual model Specification Sheets for complete specifications listings. Note: Orange Research instruments use long life, hermetically sealed reed switches. Depending on the load, reed switches can be expected to provide between 1-5 million operations at 240VAC/ 50W and 5-10 million operations at 110VAC/ 50W.

To provide maximum life it is recommended that the proper contact protection be applied to reduce or eliminate arcing when switching inductive loads. For example, AC circuits could use a 100 ohm 1/4 W resistor and 0.1mfd, 600V capacitor in series across the contacts. For DC circuits use a 1N4004 diode (or equivalent) that is connected cathode-to-positive across the inductive load.

Ask about our High Voltage and High Temperature switches!

Refer to our Instruction Sheets for schematics on our switches and relays.

Transmitters:

Our instrument sensors include a magnet that moves with the sensor as the pressure or flow conditions change. Our transmitters incorporate a Hall effect sensor that transforms that movement into an electrical output. As the conditions change and the sensor moves into proximity to the Hall effect sensor there is a change in output from the Hall effect sensor that is proportionate to the DP reading or flow rate.

Every transmitter is capable of providing a voltage, current, frequency, RS232 or relay output. The user simply selects the output they require. Temperature compensation ensures that the output of the transmitter does not drift.

Each transmitter can be installed as a three or four wire connection. The safety ratings of the switch enclosures also apply to the transmitters. | |||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||

| MOUNTING OPTIONS: DIFFERENTIAL PRESSURE INSTRUMENTS

A variety of brackets are available for mounting instruments on walls, panels and pipes. Surface plates flush mount instruments without external switches. Some have extended angle brackets to hold models with Nema 4X switch or relay enclosures. Pipe clamps mount units to various size rods or pipes.

|