Principal Characteristics

|

andecologicalrefrigerants(HFC)/zoom/21462480903_2.jpg) |

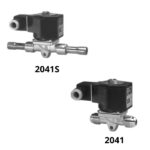

Technical specifications

| Size | Connection | Catalog Nr. | Kv Coefficient | Weight in Kg. (*) | Repair Kit Code | |

| 1/4″ | Flare | 2041BT2 | 0,16 | 0,49 | K41T1 | |

| Soldar odf | 2041BT2S2 | 0,48 | ||||

| 3/8″ | Flare | 2041BT3 | 1,20 | 0,54 | K041T1 | |

| Soldar odf | 2041BT3S3 | 0,59 | ||||

| 1/2″ | Flare | 2041BT4 | 1,40 | 0,55 | ||

| Soldar odf | 2041BT4S4 | 0,59 | ||||

| 5/8″ | Soldar odf | 2041BT4S5 | 0,60 | |||

| Flare | 2041BT5 | 2,50 | 0,92 | K41T3 | ||

| Soldar odf | 2041BT5S5 | 0,95 | ||||

| 2/4″ | Soldar odf | 2041BT5S6 | 2,70 | 0,96 | ||

| 7/8″ | Soldar odf | 2041BT5S7 | 0,97 |

- (*) The weight includes valve and coil.

- General dimensions

andecologicalrefrigerants(HFC)/zoom/32015676209_3.jpg)

| Connection | Catalog | Part Nr | DIMENSIONS (mm) | |||||||

| fA | B | C | D | E | F | G | fH | |||

| 1/4″ FLARE | 2041BT2 | 041BT2 | – | 30 | 53 | 7,7 | 64,3 | 59 | 87,3 | – |

| 1/4″ ODF | 2041BT2S2 | 041BT2S2 | 6,40 | 115 | 115,3 | |||||

| 3/8″ FLARE | 2041BT3 | 041BT3 | – | 40,5 | 67 | 17,5 | 65 | 77 | 96,3 | 5 |

| 3/8″ ODF | 2041BT3S3 | 041BT3S3 | 9,66 | 150 | 132,8 | |||||

| 1/2″ FLARE | 2041BT4 | 041BT4 | – | 77 | 96,3 | |||||

| 1/2″ODF | 2041BT4S4 | 041BT4S4 | 12,76 | 150 | 132,8 | |||||

| 5/8″ ODF | 2041BT4S5 | 041BT4S5 | 15,9 | |||||||

| 5/8″ FLARE | 2041BT5 | 041BT5 | – | 54,5 | 98 | 19 | 75,5 | 102 | 108,8 | 7 |

| 5/8″ ODF | 2041BT5S5 | 041BT5S5 | 15,9 | 170 | 142,8 | |||||

| 3/4″ ODF | 2041BT5S6 | 041BT5S6 | 19,1 | |||||||

| 7/8″ ODF | 2041BT5S7 | 041BT5S7 | 22,3 | |||||||

andecologicalrefrigerants(HFC)/zoom/41672390740_4.jpg)

- NOTES: (**) Upon request Pg11 or 1/2″ NPT conduit.

- Optional luminous indicator.

-

Recommendations for the installation of solenoid valves - Place a strainer immediatly upstream of the valve.

- Most favourable position: Upon a horizontal pipe line with the coil in the upward position.

Instructions for brazing

- Desassemble the valve leaving only the body.

- Place a wet rag on the body as shown above to avoid excessive heat build-up.

- In the case of extended copper tubes it is not necessary to disassemble the valve.

- When reassembling the valve proceed with caution in the handling of the different pieces, particularly with the Teflon diaphragm.

andecologicalrefrigerants(HFC)/zoom/5947597200_5.jpg)

-

Typical circuit for the Dt regulation for chambers with relative humidity control. - 1. Strainer

- 2. Solenoid valve

- 3. Thermostat

- 4. Check valve

- 5. Thermostatic expansion valve

- 6. Evaporator

- 7. Pressure-switch

andecologicalrefrigerants(HFC)/zoom/61611159426_6.jpg)

This system replaces the suction pressure regulator valve.